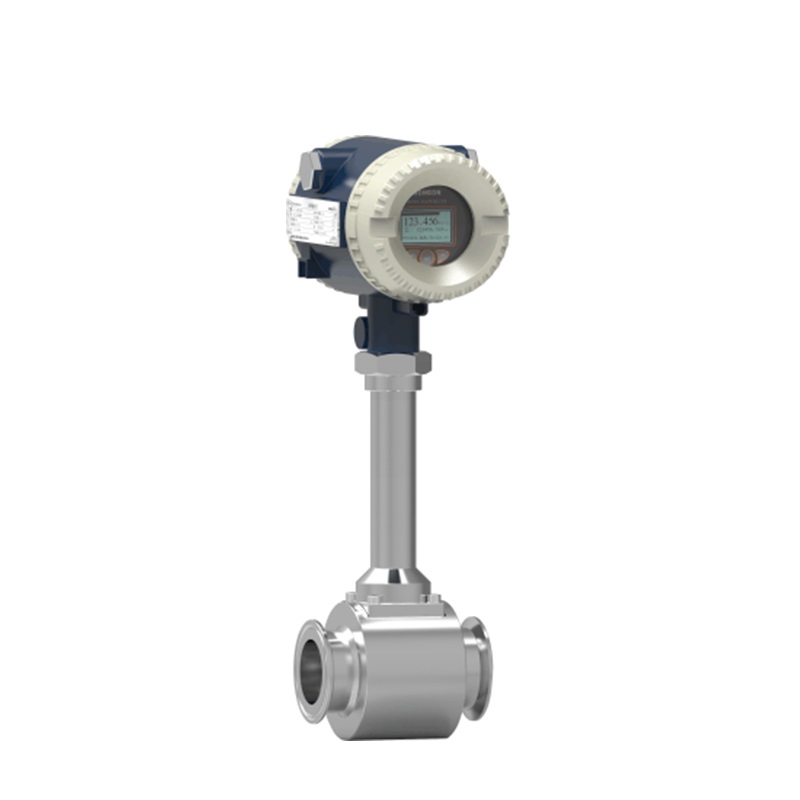

2022 High quality Vortex Flow Meter Applications - JEF-400 Series Vortex Folwmeter –

2022 High quality Vortex Flow Meter Applications - JEF-400 Series Vortex Folwmeter – Detail:

Product Description

Vortex flowmeters are used in numerous branches of industry to measure the volume flow of liquids, gases and steam. Applications in the chemicals and petrochemicals industries, for example, in power generation and heat-supply systems involve widely differing fluids: saturated steam, superheated steam, compressed air, nitrogen, liquefied gases, flue gases, carbon dioxide, fully demineralized water, solvents, heat-transfer oils, boiler feedwater, condensate, etc.

Product Details

Application

Steam, Air, Compressed air, Biogas, Methane gas, CO2, Oxygen(O2), Helium gas, LNG, N2, KEROSENE, Methane gas, Water.

Features

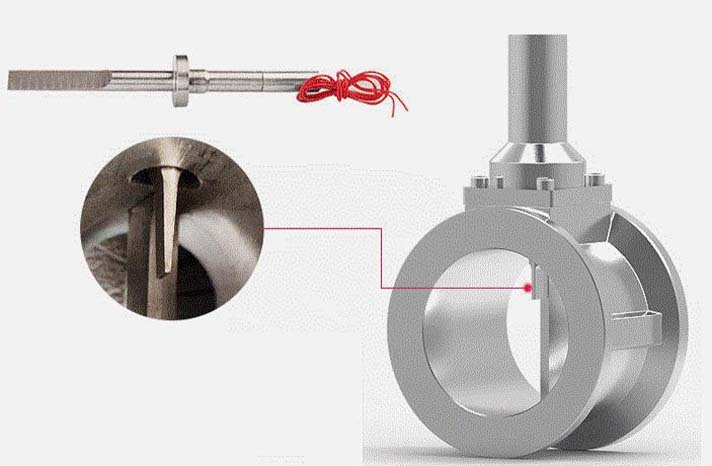

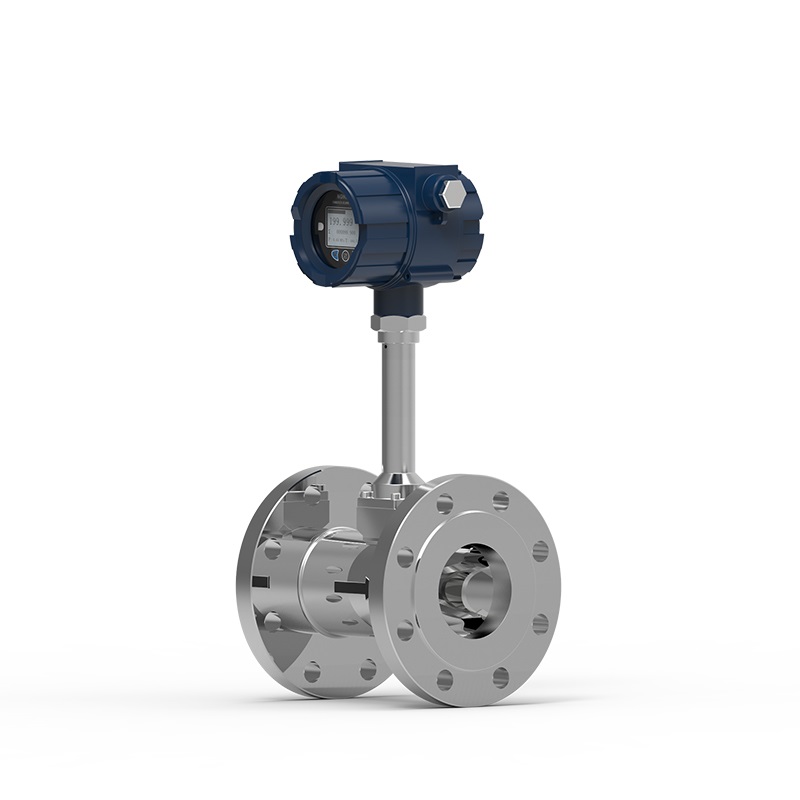

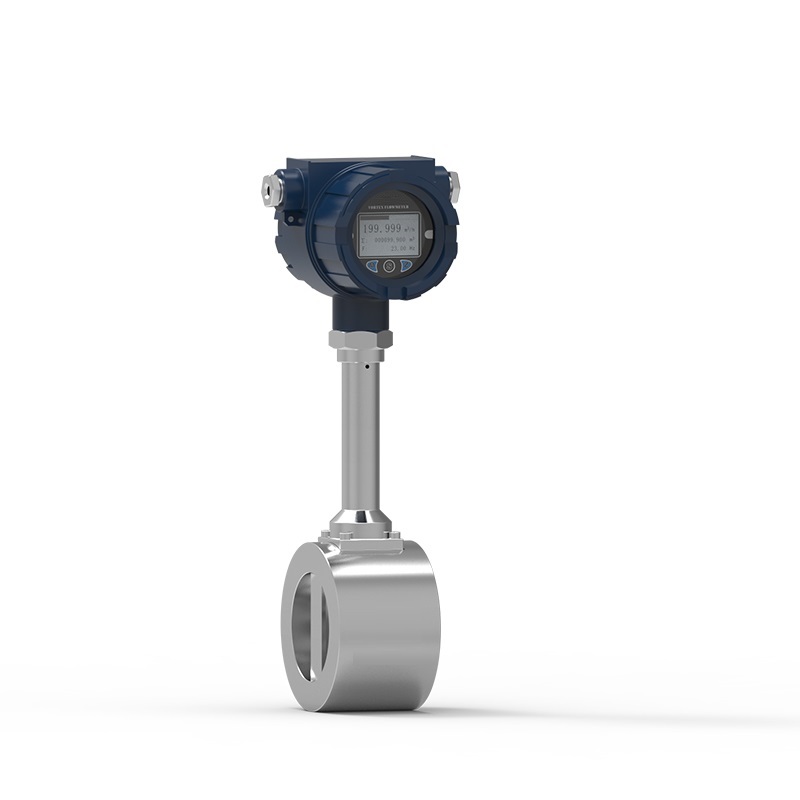

● In-line flange process connection vortex flow meter, sensor size up to 12 inch

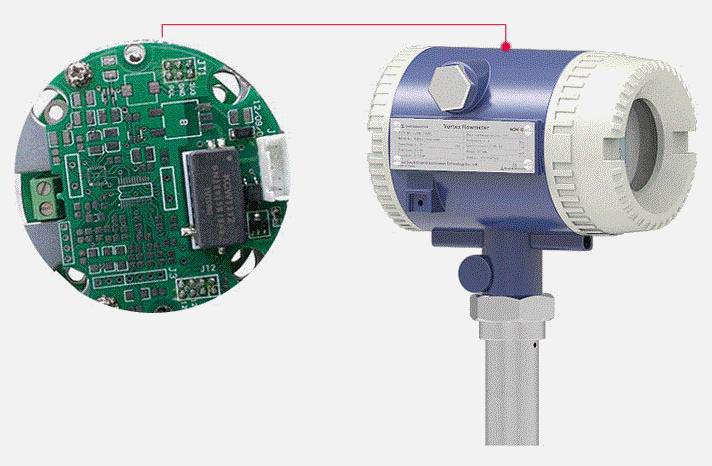

● Powerful and easy configuration vortex flow transmitter

● Easy installation

● All stainless steel vortex flowmeter

● Little pressure loss

● Large measuring range and high accuracy

● Accurate flow measurement is not affected by the fluids density, pressure, temperature, also viscosity

● No moving mechanical parts inside the vortex flow sensor, so high reliability and low maintenance

● Low price cost flow meter

Product Portfolio

Specifications

|

Measuring Medium |

Gas, Liquid, Steam | |

|

Accuracy |

Liquid | ±1% |

| Gas Steam | ±1.5%~±1% | |

|

Range ratio |

1:10 1:15 1:20 |

|

|

Nominal diameter |

DN15 DN20 DN25 DN32 DN40 DN50 DN65 DN80 DN100 DN125 DN150 DN200 DN250 DN300 |

|

|

Type |

Material | 304L SS |

| 316L SS | ||

| Shape | Integrated type (Local display) | |

| Split type | ||

| Connection | Flange type | |

| Clamp-on type | ||

| Plug-in type | ||

|

Signal Input |

Pulse signal, 4- 20 mA | |

|

Data Interface |

RS-232, RS485, HART, Modbus,Profibus | |

|

Working Environment

|

Medium temperature | -40°C ~ +250°C |

| -40°C ~ +320°C | ||

| Environment condition | Temperature: -20°C ~ +60°CHumidity: 5% ~ 95 % | |

|

Power Supply |

Battery, 24V | |

|

Protection |

IP65, IP68 | |

|

Explosion-proof |

ExiaIICT5, ExdIIBT6 | |

Application Range-Flange type

|

Diameter |

Liquid medium Range(m³/h) |

Gas medium Range(m³/h) |

Connection |

Pressure Mpa |

|

DN15 |

1.2-6.2 |

5-25 |

Flange |

2.5/1.6 |

|

DN20 |

1.5-10 |

8-50 |

Flange |

2.5/1.6 |

|

DN25 |

1.6-16 |

10-70 |

Flange |

2.5/1.6 |

|

DN32 |

1.9-19 |

15-150 |

Flange |

2.5/1.6 |

|

DN40 |

2.5-26 |

22-220 |

Flange |

2.5/1.6 |

|

DN50 |

3.5-38 |

36-320 |

Flange |

2.5/1.6 |

|

DN65 |

6.2-65 |

50-480 |

Flange |

2.5/1.6 |

|

DN80 |

10-100 |

70-640 |

Flange |

2.5/1.6 |

|

DN100 |

15-150 |

130-1100 |

Flange |

2.5/1.6 |

|

DN125 |

25-250 |

200-1700 |

Flange |

1.6/1.6 |

|

DN150 |

36-380 |

280-2240 |

Flange |

1.6/1.6 |

|

DN200 |

62-650 |

580-4960 |

Flange |

1.6/1.6 |

|

DN250 |

140-1400 |

970-8000 |

Flange |

1.6/1.6 |

|

DN300 |

200-2000 |

1380-11000 |

Flange |

1.6/1.6 |

Application Range- Plug-in type

|

Diameter |

Measuring Range(m³/h) |

Diameter |

Measuring Range(m³/h) |

||

|

Liquid |

Gas |

Liquid |

Gas |

||

|

DN250 |

80-1150 |

1060-10600 |

DN900 |

970-12000 |

13000-130000 |

|

DN300 |

13-1400 |

1540-15400 |

DN1000 |

1130-16900 |

17000-170000 |

|

DN400 |

180-2700 |

2700-27000 |

DN1100 |

1450-18000 |

19000-190000 |

|

DN500 |

280-4200 |

4240-42400 |

DN1200 |

1630-24400 |

24400-244000 |

|

DN600 |

410-6100 |

6100-61000 |

DN1300 |

2020-25300 |

27000-270000 |

|

DN700 |

580-7300 |

7800-78000 |

DN1400 |

2350-29500 |

31000-310000 |

|

DN800 |

720-10800 |

10850-108500 |

DN1500 |

2550-38000 |

38200-382000 |

Configuration

| Type | Shape | JEF-401 Integrated type (Local display) | |||||||

| JEF-402 Split type | |||||||||

| Material | 1 304L | ||||||||

| 2 316L | |||||||||

| Connection | F Flange type | ||||||||

| C Clamp-on type | |||||||||

| P Plug-in type | |||||||||

| Compensation | □N No | T Temp. | P Pressure | TP Both | |||||

| Medium | □1 Liquid | 2 Gas | 3 Compressed air | 4 Steam | |||||

| Nominal diameter | DN mm | ||||||||

| Power | 1 Battery | 2 24V | |||||||

| Signal output | 1 No | 1 Pulse signal | 2 4-20mA | ||||||

| Data Interface | A RS-232 B RS485 H HARTM Modbus P Profibus other | ||||||||

| EX grade | 1 No | 2 ExdIIBT6 | other | ||||||

Example: JEF4021F-TP-1DN100-1-2-B-2

PS: Standard configuration = 316L Integrated flange type vortex flowmeter +

Temperature & pressure compensation + Liquid DN100mm + Battery+4-20Ma+RS-485+ ExdIIBT6

Product detail pictures:

Related Product Guide:

Our pursuit and corporation aim should be to "Always satisfy our consumer requirements". We carry on to build and style and design remarkable quality items for both our outdated and new clients and reach a win-win prospect for our clients at the same time as us for 2022 High quality Vortex Flow Meter Applications - JEF-400 Series Vortex Folwmeter – , The product will supply to all over the world, such as: Portugal, Rotterdam, Nigeria, To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we'll prove our capability. With your kind help, we believe that we can create a bright future with you together.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.